I. Basic composition and maintenance specifications of the measuring machine

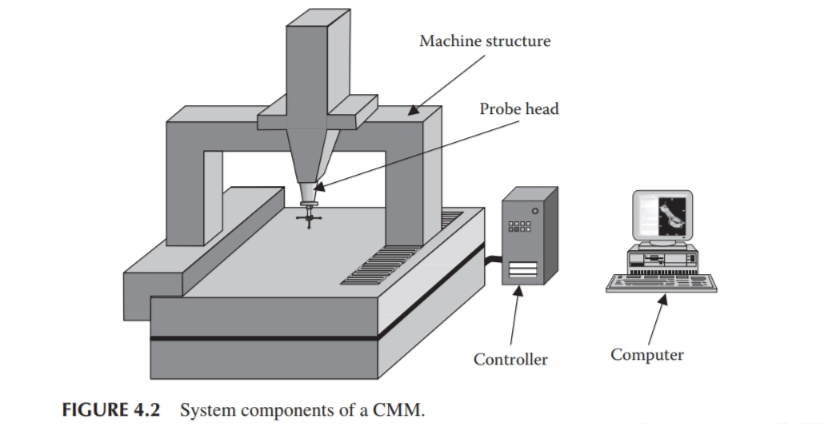

1. Mechanical system: mainly composed of workbench and three-axis guide rail, the material is composed of granite, good temperature stability. Air float guide rail, DC servo motor, synchronous belt drive. Air flotation

The block is suspended on the guide rail, and the distance from the guide rail is very narrow, so pay attention to keeping the guide rail clean. The small hole diameter of the air float block is very small, and it is easy to be blocked by the dust in the gas, so

To ensure that the machine air intake clean. When loading and unloading parts, it should be noted that the guide rail surface can not be scratched and collided with the workpiece.

2. Grating ruler and reading head: each axis has a pair, is a length measuring element, belongs to the photoelectric element, attached dust will affect the normal work. Don't wipe unless you make a mistake in reading.

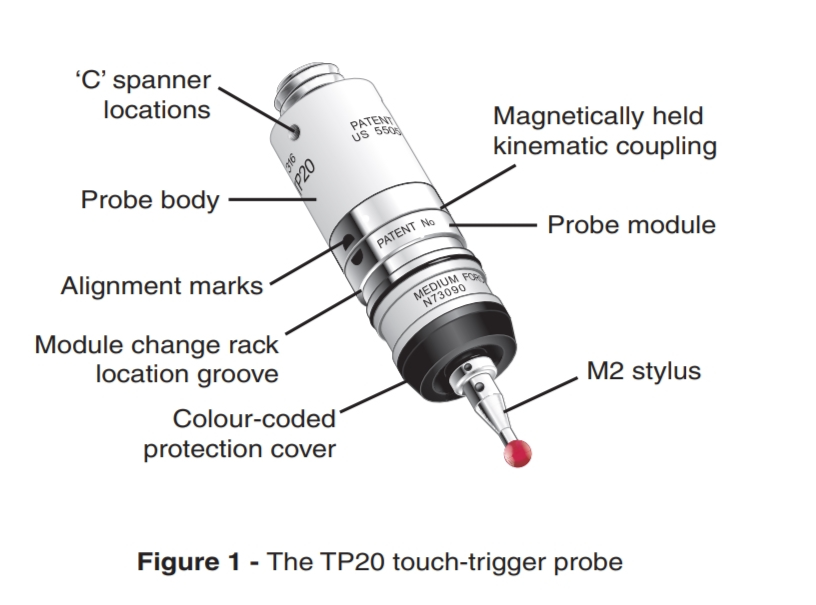

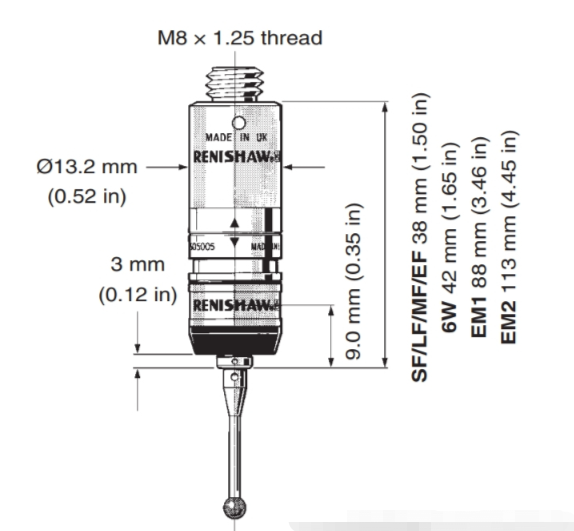

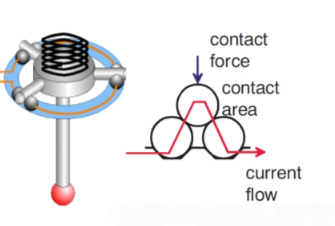

3. Probe system: mainly trigger probe, is the only part in contact with the workpiece, each test is a point when the probe sensor has a "contact - bias - signal - reply" process. measuring

A serious collision of the head will lead to reduced life or damage, and long-term use will make the probe easy to fatigue and reduce sensitivity.

4. Computer and electrical systems: are machine control and data processing components. Pay attention to the loose phenomenon of the plug-in and the stability of the power supply.

The measuring machine is mainly affected by the following 2 aspects of the external environment:

1. Power supply: This is the most influential part of the machine electrical system, voltage instability, power pollution will lead to system failure. Therefore, a voltage regulator with voltage regulator and filter functions

II. Principle of coordinate measurement

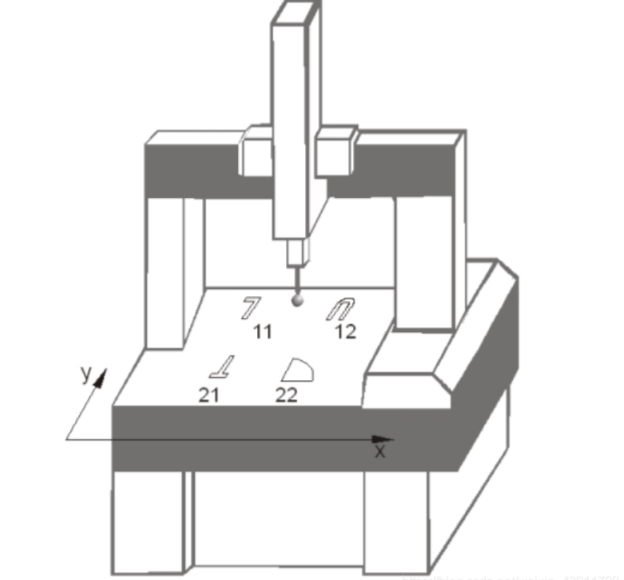

The measured object is placed in the three-coordinate measuring space, and the coordinate values of each measuring point on the measured object are obtained through the sensor. The number of the measured object is calculated by using the least square method or other calculation methods

Any size and shape errors.

Description of a specific measurement process:

1. Before starting the measuring machine, drain the water in the gas tank. Check whether the data of temperature and humidity instruments in the work room meet the requirements. If the data exceeds the standard, the auxiliary equipment should be turned on and returned to the requirements before working.

When the difference in values is too large (winter and summer season), the air conditioner should run uninterrupted!

2. Check whether the air pressure meets the requirements, and whether the total air pressure of the machine can reach 0.4mpa-0.65mpa

3. Turn on the computer and control the system. (Just turn on the computer with the hand) Open the software and start a new project.

5. Select the probe and correct the Angle needed.

6. Geometric elements are measured according to the requirements of the measured part

7. Evaluate geometric tolerances and output reports

8. End the measurement and save items, exit the software, and shut down the controller

s needed. Ups uninterruptible power supply is also recommended.

2. Gas supply: In order to prevent the blockage of its gas to the gas float block, the air source should be ensured to be dry.

3. Environmental vibration, dust, temperature and humidity: vibration will affect the accuracy of the machine when working, temperature has a great impact on the length measurement, humidity will lead to electrical, and mechanical problems

Road.

III. Basic principle of trigger probe

The probe is a data acquisition system of a measuring machine consisting of a sensor, a ruby needle mounted on the front of the sensor, and a side head seat that allows the sensor to be turned to various positions. In electrical terms.

The sensor is a switching device, and when the ruby needle hits the object under test, the needle is biased. A pulse signal is generated inside the side head to allow the measuring machine system to latch the current seat.

Mark the position, this position is the position of the coordinates of the red main stone.